Operators need to increase cash flow and decrease CAPEX while simultaneously improving production. Hexion has developed a new technology to help operators achieve this daunting task. Hexion’s PropCure on-the-fly curable resin coating allows operators to coat sand for hydraulic fracturing on location in the blender tub.

PropCure coating is the next generation of curable resin coating technology for proppants. It consists of a two-part system that is combined with a simple static mixer on the frac site. The PropCure coating is added directly to the blender tub using standard liquid additive pumps. The unique chemistry has an affinity for proppants, so it coats the proppant and not the equipment.

Once downhole, the PropCure coated proppant acts just like a traditional curable resin coated proppant. It provides all the same benefits of grain-to-grain bonding and keeps proppant in fractures—where it's intended to stay.

PropCure coating provides significant bond strength to control proppant flowback. The coating is effective at a wide range of bottomhole temperatures (105°F - 350°F).

|

Left: Sand treated with PropCure coating forms a consolidated proppant core. |

|  |

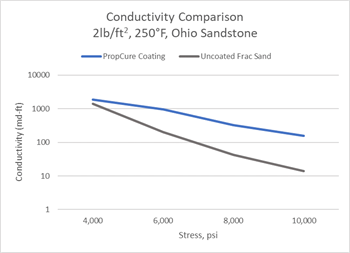

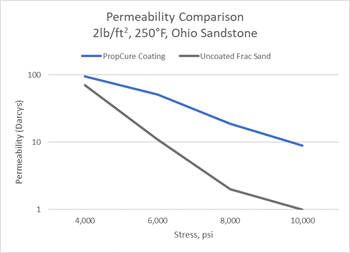

| Closure Stress, psi | 4,000 | 6,000 | 8,000 | 10,000 | Closure Stress, psi | 4,000 | 6,000 | 8,000 | 10,000 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Conductivity (md-ft) | Permeability (Darcy's) | |||||||||

| PropCure Coating | 1860 | 962 | 328 | 157 | PropCure Coating | 95 | 51 | 19 | 9 | |

| Uncoated Frac Sand | 1411 | 202 | 43 | 14 | Uncoated Frac Sand | 71 | 11 | 2 | 1 | |

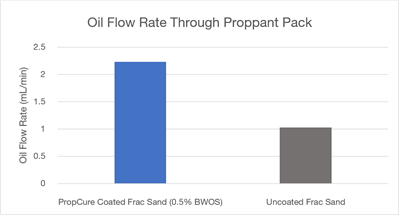

By altering the relative permeability of the proppant pack, PropCure coating provides more than two times higher flow rate compared to uncoated frac sand. Running this technology even at low concentrations can reduce or eliminate the need for additional surfactants.