Putting sustainability at the core of our business means building from the inside out. That starts with the values that guide us and extends to how we operate in every plant, every day.

Our Manufacturing Excellence program creates an environment for learning, problem solving and engagement that supports our values. As a member of the American Chemistry Council, Hexion fully supports the Council’s Responsible Care® program through:

The Geismar plant had a need to reduce costs for interplant truck transfers, and had rainwater that was captured on site, but could not be used. By thinking outside of the box, and recognizing that the one pipeline could help both challenges a team of associates found a creative way to use 4.8 MM gallons of rainwater, offsetting freshwater purchases and waste treatment costs. That is ten times more annually than in prior years!

A project team of operations and Six Sigma associates set out to identify and implement solutions to reduce truck transfers of product between two physical locations separated by nearly ½ mile. These transfers were required to meet customer demands at the two separate locations.

Through their investigation, the project team identified that a pipeline would not only eliminate trucked interplant transfers, but could also be used to transfer rainwater captured in the tank farm area between the two locations for beneficial reuse in the process and the necessary flushing of the piping after each transfer.

As a result of this pipeline not only was the site able to increase their rainwater consumption, but were able to eliminate 1,812 truck shipments annually between the two locations and the resulting fuel use, CO2 emissions and potential safety and environmental exposures.

Reducing waste in manufacturing - The Hexion team at our Deer Park, Texas facility used a combination of hardware and software upgrades and improved employee training to significantly reduce the creation of undesired byproducts in its production processes. The improvements reduced waste by 400,000 pounds in 2016, resulting in a savings of $400,000. Just as importantly, the project created more ownership from the ground floor in thinking and acting to minimize waste production and helped reduce operational complexity and the potential for mistakes.

At Hexion, we have a clear priority around working safely and are committed to the possibility of an incident-free environment for all of our associates and stakeholders. We are responsible, engaged and focused on reducing exposures across the value chain. Our people continuously look for ways to eliminate exposure and work to create a culture that supports trust, open communication and continuous learning.

In 2014, Hexion created a cultural change program targeting a reduction in Severe Incident Factors (SIF). SIFs are defined as high-risk work activities which, if not properly controlled, could result in serious injuries, permanent disabilities, and/or fatalities. Called “Get Zero. Get Home.” this cultural shift in thinking has increased awareness of workplace conditions and activities that have the possibility of putting associates, contractors and visitors at risk. With our diligent focus and the continued execution of our health, safety and environmental strategy in 2014, Hexion experienced the following improvements when compared to 2013:

From 2013 to 2017…

A 52 percent improvement in environmental incidents,

A 63 percent improvement in Hexion SIF recordable incidents and

A 67 percent reduction in SIF recordable incidents involving contractors.

Placing sustainability at the core of our business means building from the inside out. It gives us the values that guide us and extends to how we operate in every facility, every day.

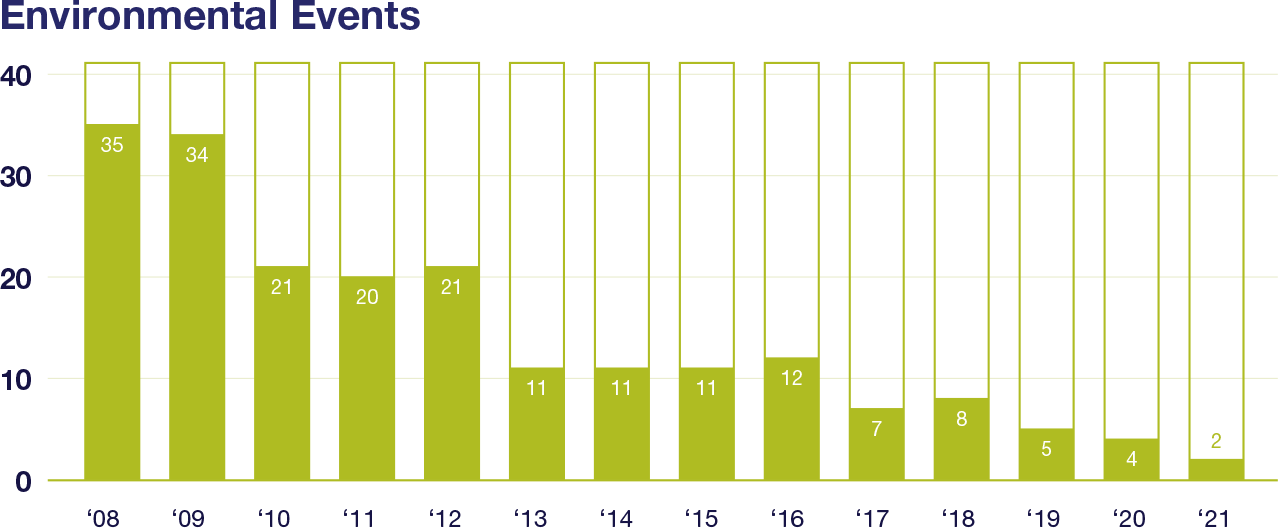

Through focused efforts to reduce spills and releases, and improved permit compliance, the Environmental Events metric has steadily declined and held steady in recent years with a 10-year reduction of over 85 percent.

Success is measured based on the following metrics:

At Hexion, efficiently managing natural resources is essential to operational excellence and the sustainability of our business and are committed to reducing our carbon footprint.